Admin | Post : 2025-05-01

Standards of heavy duty racking materials

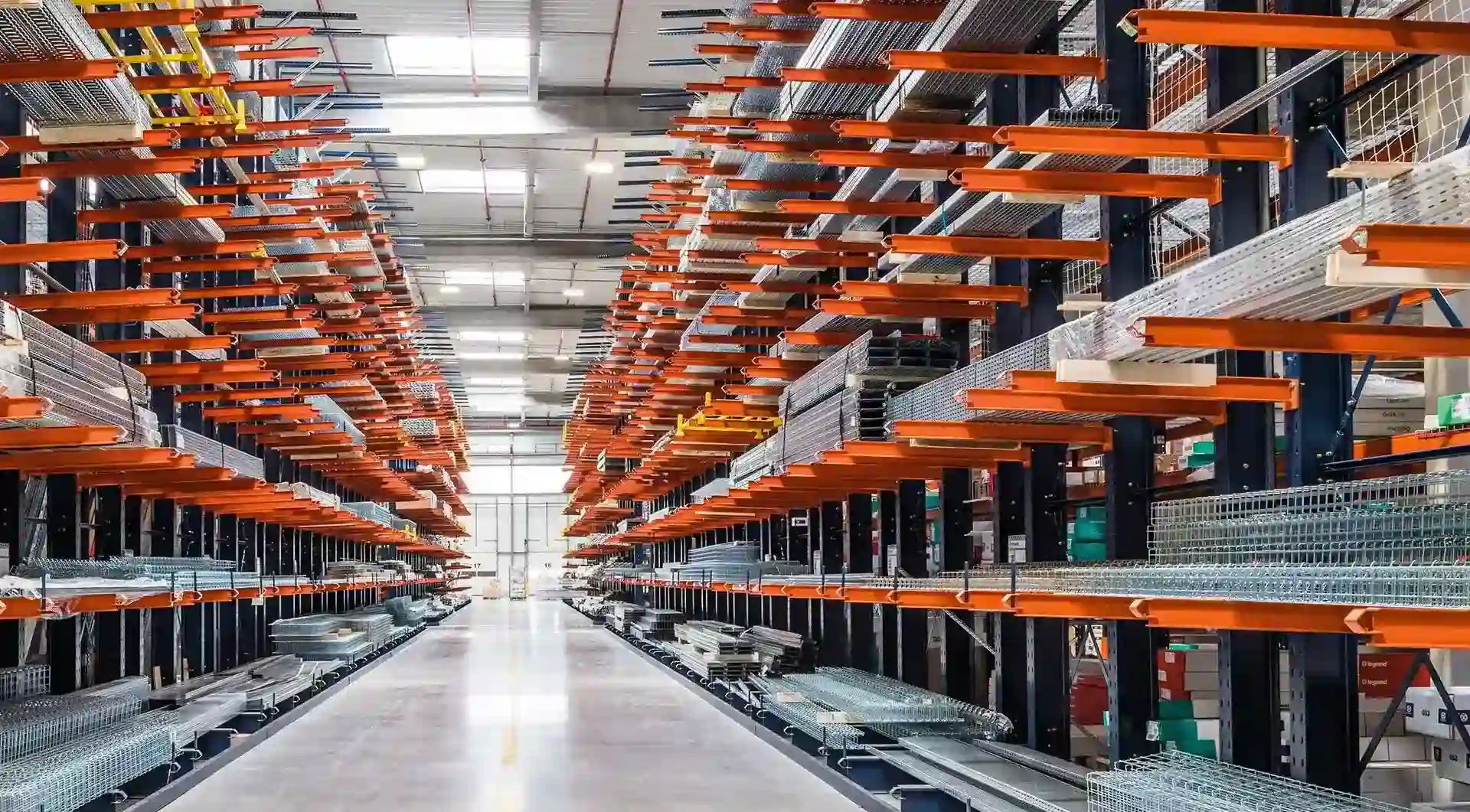

Heavy-duty racking solutions from racking and shelving providers in the UAE function as necessary storage systems for warehouses, together with factories and industrial sites.

The evaluation process of standards for heavy-duty racking material helps determine their reliability. Before purchasing a racking system, do you think there is a way to verify its reliability? Yes, of course, An evaluation of the materials' standards will reveal all necessary information.

In this blog, we will provide critical information about fundamental standards you should look for when you need to select heavy-duty racking materials.

Why Standards Matter in Heavy-Duty Racking?

Quality, alongside durability and safety, is ensured by standards. Any small weakness in the material qualities used for heavy-duty racks will affect workers. Manufacturers maintain industry-standard procedures to build racking systems that execute effectively under actual application conditions. The selection of a heavy-duty racking system should prioritise the following details.

• Load-bearing capacity

• Material thickness and grade

• Welding and joint quality

• Coating and corrosion resistance

• Certifications and compliance

Check the following:

1. Steel Quality and Grade

The materials that are used to build heavy-duty racks consist of cold-rolled steel, which exhibits exceptional strength with consistent properties. The maximum weight capacity of racks depends mainly on the steel quality they are built from.

Look for:

• High tensile strength steel (often over 350 MPa)

• Certified materials as per ISO 657 or EN 10025 standards

• Clear labelling of material grade, such as S235 or S355

The numerical classifications specify the yardstick for measuring steel yield strength, where higher grades indicate improved bending resistance.

2. Material Thickness

Steel component thickness controls how much weight racks can bear. Common standards to look for:

• Upright frames: 1.5mm to 2.5mm thick

• Beams: 1.5mm to 2.0mm thick

The usage of dense materials gives strong resistance, but consider your budget in the process. A perfect balance exists between finding a material that matches your storage capacity requirements and staying within your budget plan. Need a consultation? Contact Warehouse Racking Solutions Dubai now.

3. Welding and Joint Standards

High-quality welding methods create an entire racking system that survives heavy loads safely. The process of welding adversely affects joint strength; if the welding is poor, it can lead to weak joints and then to dangerous failures.

What to check for:

Racked elements must have welding specifications which comply with ISO 3834 or AWS D1.1 standards.

Clean, uniform welds without visible cracks or porosity

Bolted joints that match industry safety protocols

4. Surface Coating and Finish

Racks are often used in areas that contain dust and moisture as well as chemical exposure. Proper surface coating of steel protects the material against rust formation. Coating types include:

• Powder coating: Durable, eco-friendly and corrosion-resistant

• Galvanisation: Great for outdoor or moisture-heavy areas

• Painted finishes: Economical and customisable

The coating material needs to meet all requirements of the ISO 12944 standard for resistance against corrosion.

5. Load Testing and Certification

Heavy-duty racks need load testing before their maximum capacity can be established to become reliable. Load charts and certificates of compliance are usually given to customers by manufacturers. Make sure you place your loads according to the capacity.

Certifications to look for:

• SEMA (Storage Equipment Manufacturers Association) guidelines

• RMI (Rack Manufacturers Institute) standards (especially in the US)

• CE certification for compliance with European standards

• ISO 9001 for quality management systems

The safety standards of products can be confirmed through certifications which demonstrate their successful testing compliance with international safety standards.

6. Custom Design and Engineering Support

If your warehouse requires individualised rack designs, check whether your supplier is offering customisation. Customising your needs will help you fit the rack perfectly in your space without having further concerns. If you need to know more about how customisation works, contact Customised Industrial Racking UAE to know more.

Here's a quick checklist before you buy:

· The steel grade and thickness clearly mentioned?

· Are welds neat and standards compliant?

· Has the product undergone load testing?

· Check if coatings are durable and rust-resistant?

· Is there any certification (ISO, CE, SEMA, RMI)?

· Is the supplier offering installation and post-sale support?

Conclusion

Heavy-duty racking systems function as a long-term investment since warehouses will be incomplete without a proper racking system. As we mentioned above, choosing a heavy-duty racking system is a process that needs consideration over time. In this blog, you will get an idea of the details to look for when you are buying a racking system. Try to take smart decisions that will help you build a safe and efficient storage for your workers. If you have concerns, connect with racking and shelving companies in the UAE; our experienced professional team will help you.