Admin | Post : 2023-04-10

5 Essential Factors to Consider When Installing Warehouse Racks

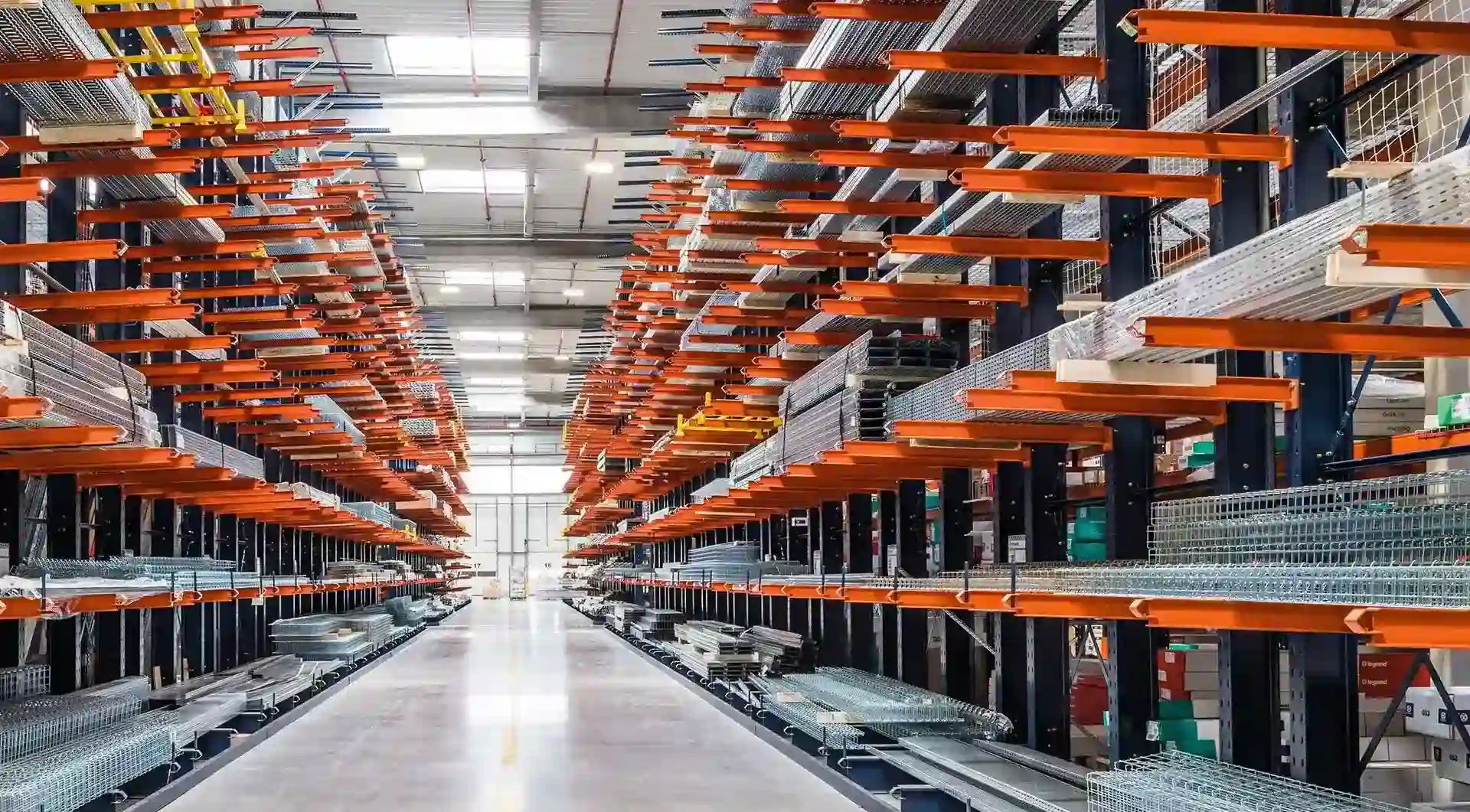

Racking and shelving provider in UAE for installing warehouse racks requires careful consideration of several essential factors to ensure optimal functionality and safety. These factors play a crucial role in maximizing storage capacity, improving operational efficiency, and protecting inventory. By understanding and addressing these key considerations, businesses can make informed decisions and create a well-organized and efficient warehousing system. This exploration highlights five essential factors that should be taken into account when installing warehouse racks, providing valuable insights for businesses aiming to optimize their storage infrastructure.

What are Warehouse Racks and Why Is It Important to Install Them Properly?

Warehouse racks are structures used to store and organize products, materials, and equipment in a warehouse or storage facility. They come in various sizes and designs to suit different storage needs and can be made from materials such as metal, wood, or plastic. If you are looking for installing racks in your warehouse, ZYCO is the best racking and shelving provider in UAE.

Proper installation of warehouse racks is important for several reasons. First and foremost, it ensures the safety of workers and the products stored on the racks. Improperly installed racks can collapse or tip over, potentially causing serious injuries or damage to products. Therefore, it is crucial to follow the manufacturer's instructions and safety guidelines when installing warehouse racks.

Additionally, the proper installation of warehouse racks maximizes the use of available space in the facility. Efficient use of space is important in any warehouse or storage facility, as it helps to increase productivity and reduce operating costs. Installing racks properly ensures that the available space is used to its fullest potential, allowing for more efficient storage and retrieval of products. Overall, warehouse racking UAE by ZYCO is an essential component of any storage facility, and it is important to install them properly to ensure safety and maximize space utilization. Here are five essential factors to consider when installing warehouse racks.

Factor 1 – Determine Your Storage Needs & Capacity

Before installing racks in a warehouse, it is essential to determine the storage needs and capacity of the facility. This process involves evaluating the types of products that will be stored, their sizes, weights, and quantities. Additionally, it is crucial to consider the frequency of product movement, as well as the methods of loading and unloading. By understanding these factors, warehouse managers can determine the optimal storage layout, rack types, and capacities necessary to maximize the available space while maintaining safe and efficient operations. Ultimately, proper planning and consideration of storage needs and capacity can help ensure a successful and productive warehouse operation. ZYCO is one of the top racking and shelving companies in UAE that provide proper planning before installing racks.

Factor 2 – Analyze the Location & Environment of Your Warehouse

Analyzing the location and environment of a warehouse is critical before installing racks. Factors such as building codes, fire safety regulations, and seismic requirements must be considered. The layout of the warehouse, including the floor plan, ceiling height, and door placement, can also affect the type and placement of racks. Additionally, the surrounding environment, such as the local climate and weather patterns, must be considered to ensure that the racks can withstand any potential hazards, such as extreme temperatures, humidity, or wind. Being one of the trustful shelving and racking suppliers in UAE, ZYCO offers the best raking services by carefully analyzing the location and environment of the

warehouse. ZYCO can select and install racks that will provide optimal storage capacity and safety while minimizing the risk of damage or disruption to operations.

Factor 3 – Choose the Right Type of Rack System

Choosing the right type of racking system for a warehouse is a crucial step in optimizing storage and workflow efficiency. Factors to consider include the type and size of the products to be stored, the weight capacity required, the available space, and the accessibility needed for picking and storing items. Before installing racks, it's important to carefully assess these requirements and consider different options such as selective, push-back, drive-in, or pallet flow racking. By selecting the appropriate racking system, warehouse managers can ensure safety, increase productivity, and maximize the use of available space. Don’t be confused while choosing the racking and shelving provider in UAE because ZYCO is the best choice for you.

Factor 4 – Measure & Plan Before Procuring & Installing Warehouse Racks

Measuring and planning are critical steps that should be taken before procuring and installing warehouse racks in UAE. It is essential to measure the available space accurately to determine the number and size of the racks required. Additionally, planning the layout of the racks ensures that they are installed in a way that maximizes the available space while providing efficient access to the stored items. It is also important to consider factors such as weight capacity, load distribution, and safety regulations when selecting and installing the racks. Proper measuring and planning can help prevent costly mistakes and ensure that the warehouse is optimized for storage and workflow efficiency.

Factor 5 – Consider Safety When Installing Racks

When installing racks, it is essential to consider safety. Racks are typically used to store heavy items, which can cause serious injury or damage if they fall. To ensure safety, it is important to choose the right type of rack for the items being stored and to install the rack properly according to the manufacturer's instructions. When considering safety, there is no doubt that ZYCO is one of the best and safest shelving and racking suppliers in the UAE. They properly anchor the rack to the wall or floor and ensure that it can support the weight of the items being stored. It is also important to periodically inspect the rack to ensure that it remains in good condition and to address any issues that may arise. By taking these precautions, you can help prevent accidents and ensure that your racks provide safe and secure storage for your items.