Admin | Post : 2025-06-14

How to label warehouse storage locations

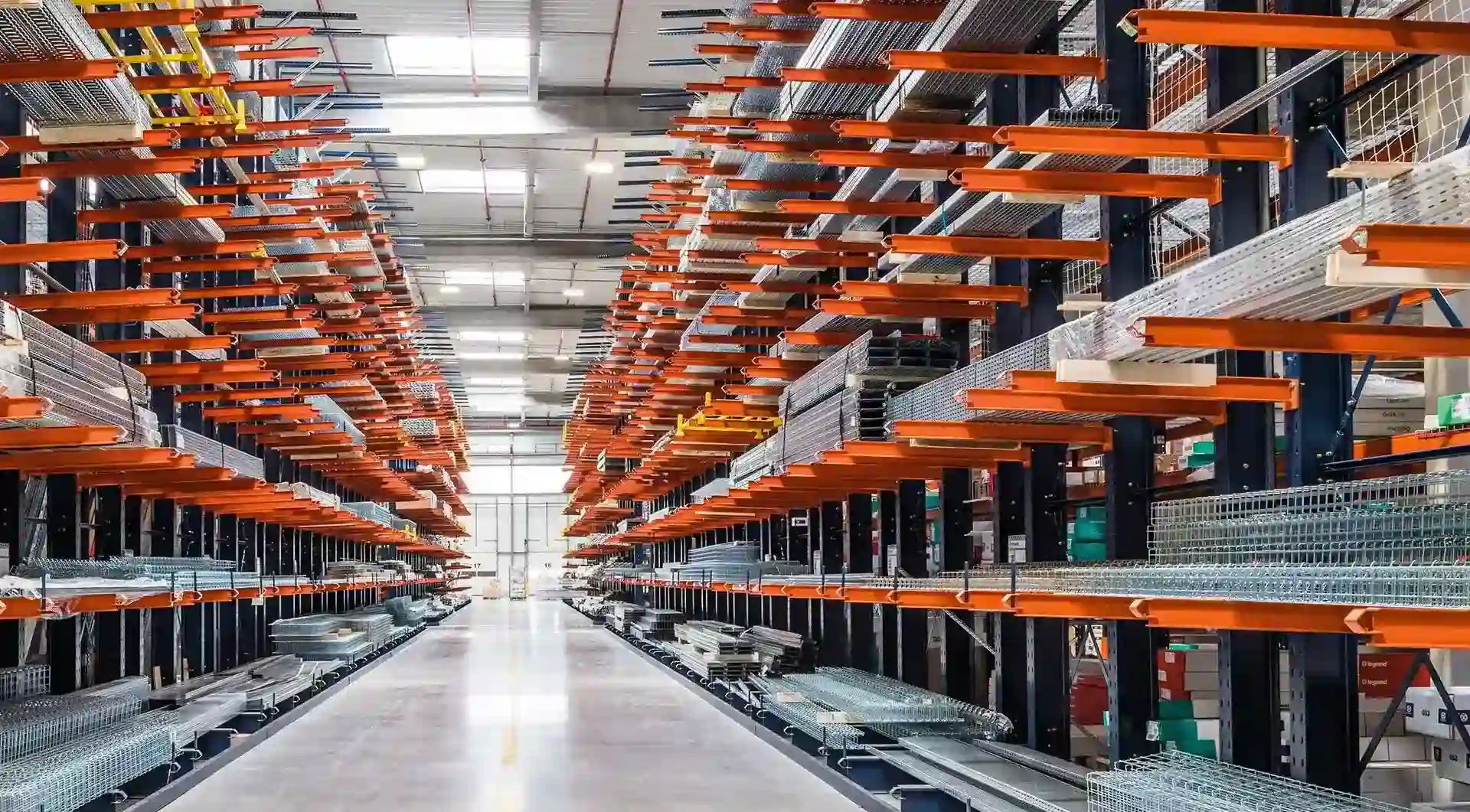

Warehouse management is important for smooth business operations. One of the main steps in achieving that efficiency is properly labeling your warehouse storage locations. Without a correct, consistent labeling system, even the most organized warehouse layout can turn out chaotic, leading to wastage of time, stock displacement and frustrated staff. As a top racking and shelving company in the UAE, we will share the best ways to label your warehouse storage to save space, boost productivity and keep operations safe.

Why labeling warehouse storage locations matters

Zyco knows how important it is to make the most of warehouse space, keeping things easy to manage. Labeling storage locations:

- Faster picking and stoking: with clear labels, it's easier for workers to locate and store items fast.

- Reduced errors: Organized storage locations reduce mistakes in inventory handling and order fulfillment.

- Better inventory tracking: Organized storage makes audits and stock counts simpler.

- Maximizing warehouse space: Good labeling helps use shelves, racks and floor space better.

- Creating a safer workplace: A neat warehouse reduces accidents and supports smooth work.

Step 1: Know your warehouse layout and needs

Before going for labeling, we recommend a complete analysis of your warehouse:

- What kind of storage systems are in place? For example, pallet racks, long-span shelving or mezzanines.

- How is your warehouse workflow structured? Know if it's receiving, storage, picking or shipping zones.

- How large is your warehouse? How many aisles, bays and levels do you have?

- What kind of products do you store? Are there any special storage requirements?

Our experienced team makes sure your labeling system matches your operational realities.

Step 2: Choose a labeling system that fits your operations

Customized Industrial Racking UAE specializes in delivering customized solutions for each client's specific warehouse setup. When it comes to labeling storage locations, some effective systems can be applied based on the warehouse size, layout and how things are organized and handled:

1.Alphanumeric labeling system

It is one of the most commonly used adjustable methods; they combine letters and numbers to represent various warehouse components. For example, aisle B, bay 3, level 2, shelf 5 becomes B-3-2-5. Staff can quickly locate items because of the clear and organized format.

2. Zone-based labeling

For larger warehouses, dividing the space into labeled zones like zone A, B, C... helps to get smoother operations. Within each zone, specific locations are labeled systematically.

3. Simple number sequence

In smaller or less complex warehouses, a basic number sequence like 001, 002, 003 is often sufficient. This simple system is perfect for layouts that are easy to navigate.

Step 3: Label every storage component

We recommend that warehouse labels should be quickly readable. Choose bold, oversized fonts with strong color contrast to make labels easy to see from afar. Durability is also another important factor; labels must withstand dust, moisture and frequent handling. Vinyl stickers or laminated labels are reliable options for long-term performance.

Step 4: Integrate with Technology

If your warehouse uses a digital system to track inventory, make sure your physical labels work with it. Barcode or QR code labels allow workers to:

- Scan items for quick identification

- Automatically update stock levels

- Track movement between locations

Why Zyco is your ideal partner for warehouse labeling and storage solutions

More than just a supplier of racks and shelves. Zyco delivers a complete solution for warehouse optimization. Whether it's pallet racking, long-span shelving or mezzanine floors, we help our clients map and label every component, boosting space efficiency and reducing operational errors.

- We recommend the ideal racking systems based on your specific storage needs.

- Design warehouse layouts customized to fit your space and budget.

- Provide long-lasting and high-quality labeling solutions enhanced with smart technology.

- Offer professional installation along with reliable ongoing technical support.

Conclusion

Labeling warehouse storage may seem small, but it greatly improves warehouse performance. It’s a simple way to increase accuracy, speed and growth potential.To organize your warehouse effectively, begin with proper labeling. And for expert support from warehouse layout to installation and labeling, connect with Warehouse Racking Solutions Dubai.