Admin | Post : 2025-03-01

How can one be an expert in choosing the right type of racking system?

Choosing the right racking system for your warehouse can be a bit confusing. You should consider several factors while selecting racking system for your warehouse, as it plays a significant role in the betterment of the space. Nowadays there are wide varieties of racking systems available in the market. When you are confused, racking and shelving providers in the UAE will help you choose the best racking solution.

In this blog, we are going to discuss the factors you should consider while buying a racking system. Let’s get into the blog to have a clear idea.

Study your space: To choose the right racking system, the first thing you need to do is study your space. It is a must to check your space so you can select the best racking system according to your needs. If you have further confusions, you can just connect with our consultation team. They will definitely have an idea to share.

Workers safety: When selecting a racking system, you should consider the safety of workers. You are installing the racking system to make their work easy, right? So causing extra inconvenience by choosing the wrong racking system will be tough for them. Make sure you select the racking system that is easy to handle for them.

Choose according to your load: You should have a clear idea of the items you are going to store in the racking system. If you need to store high loads, you should choose; assessing how much weight you need to store will help you choose the right racking system with the right load capacity. This will also help when you need to do a deep clean in the warehouse or otherwise; it will be tiring to handle the heavy racking system. To clarify, book a consultation now with warehouse racking solutions Dubai.

Racking System Type: Knowing the type of racking system will help you choose according to your needs.

We provide:

· Selective pallet racking—ideal for direct access to each pallet.

· Long-span racking system: Optimal solution for storing heavy as well as medium-sized products

· Drive-in pallet racking system: Enables efficient storage of pallets at high densities because forklifts access deep storage zones through its designed system structure, which minimizes required floor space.

· Very narrow aisle pallet: Makes efficient use of space by retrofitting narrow aisles, which necessitates special forklifts to operate smoothly.

· Double deep pallet racking: Allows stacking pallets in two deep layers per bay, thus reducing the total number of required aisles.

· Multi-tier racking system: Utilizes vertical warehouse space through additional levels, which benefits hand-picking operations of small items in storage facilities.

· Rack-supported mezzanine: Connects to storage racking to produce extra storage along with operational areas above existing racks.

· Galvanized racks: These racks maintain their resistance through galvanization to withstand moisture-rich environments throughout cold storages and warehouses located outside.

· Carpet storage racking: Help to organize carpet rolls both vertically and horizontally, thus preserving their quality and maximizing available space.

· Tyre racking system: Represents a warehouse solution designed specifically for automotive storage, which provides easy access and organized tire stacking in automotive warehouses.

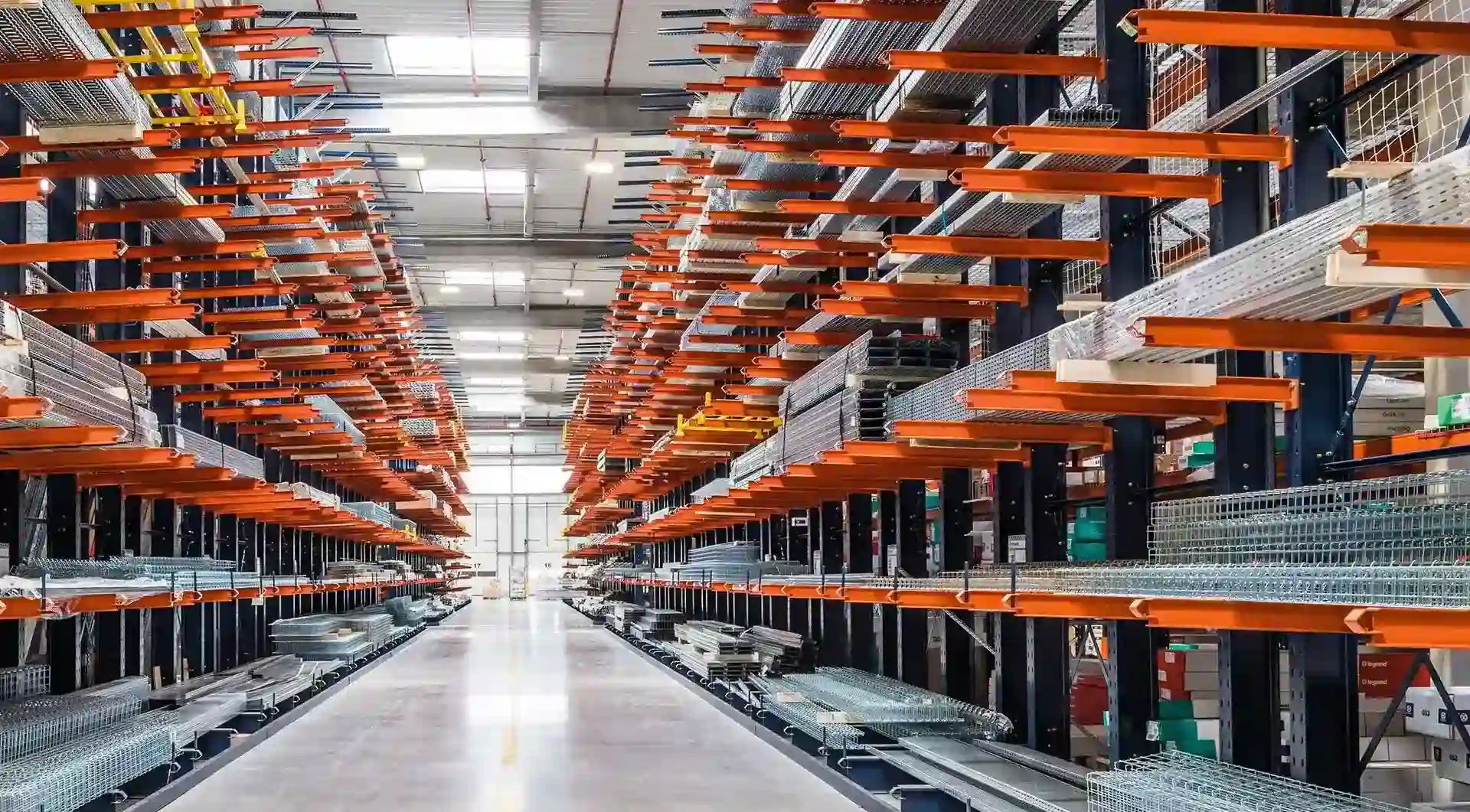

· Cantilever racking system—suitable for long or bulky items like pipes or timber.

Easy accessibility and operations: While selecting the racking system, you should know how workers are going to use them, ensure compatibility with workers, or how the materials stored in the racking system will be used.

Durability & Material: Choosing a racking system that has high quality, with proper coatings for corrosion resistance, plays a crucial role in the long-lasting nature of your racking system. Ensure all the safety standards; check whether the racking system is suitable for your rules and regulations that you follow in your warehouse.

Flexibility & Scalability: Selecting a racking system that is flexible and can be reconfigured will help if there is a situation that comes with the need for relocation as your business grows. Try to be futuristic. We provide the best relocation service for our customers; if you need help, connect with our relocation team.

Safety & Compliance: After purchasing, try to maintain the racking system as much as possible. Investing in a racking system is a one-time investment. Try to install fire safety regulations, safety barriers and rack protectors to prevent damage.

Budget & Cost Efficiency: As there are wide varieties of options available in the market, look for the best when it comes to solutions for your warehouse. Compare initial costs, long-term maintenance and return on investment. Consider Zyco, we provide the best racking solution in the UAE since 2022, Contact Heavy Duty Racking in Dubai now.

Why choose Zyco?

· Years of experience: Throughout the year, we have served many customers to satisfy their warehouse solution needs.

· Expertise: We have proved our expertise by providing premium racking solutions for our clients that are worth the purchase.

· 1000+ happy customers: We are proud to have served this many clients over the years. Our customers are the testament to our growth.

· Team: Our team deserves appreciation for the hard work they have put in to serve the clients from consultation to installation. Customized Industrial Racking UAE team will help you choose the perfect racking system by visiting your space.

Conclusion

When you need to buy the perfect racking solution, connect with us. Our team will help you from consultation to installation and maintenance. As we discussed, make sure you consider all the factors to choose the right one for your needs. If you need to keep your warehouse tidy and neat, you should invest in a racking system to have uniformity. Contact us for a better racking solution.