Admin | Post : 2023-03-03

Exploring the Advantages of Cantilever Racks and How They're Revolutionizing Storage Solutions

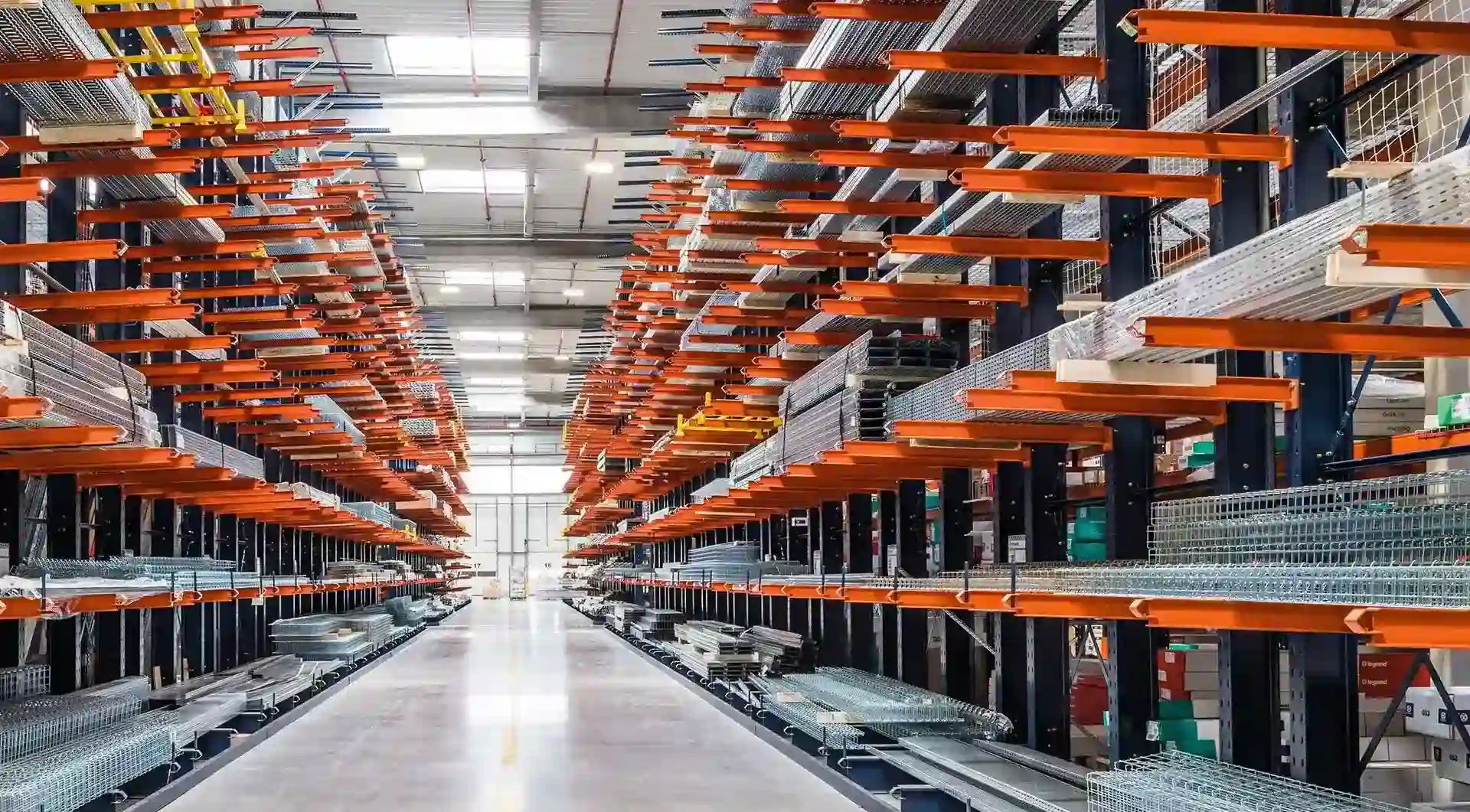

Cantilever racking systems in the UAE provide a revolutionary storage solution with multiple advantages for efficient inventory management. These specialized racks are designed with extended arms, allowing for the storage of long, bulky, and irregularly shaped items, such as lumber, pipes, and furniture. By eliminating the need for vertical supports in the front, cantilever racks provide unobstructed access to stored items, maximizing space utilization and streamlining warehouse operations. This article delves into the advantages of cantilever racks and highlights how they are revolutionizing storage solutions in various industries, enabling businesses to optimize their storage capacity, enhance efficiency, and improve overall productivity.

What is a Cantilever Rack and How Does it Work?

One of the greatest pallet-racking systems is cantilever racking, which has single columns, adjustable arms, and strong bases. These systems do not have any horizontal beams that obstruct the loading and unloading of lengthy, oddly shaped objects, in contrast to conventional pallet-racking systems. Zyco is the best provider of cantilever racking systems in the UAE.

Cantilever racks are made to make it simple to store and retrieve items of various weights, lengths, and sizes. It does not need uprights, they enable simple product accessibility, selectivity, and great down-aisle density. Cantilever systems can offer a wide range of loading options that can be tailored to your storage application by offering a variety of arm configurations. Roll-formed and structural cantilever racking are the two varieties that are offered.

Roll-Formed Cantilever Racking: Roll-formed cantilever pallet racks are made of heavy-gauge roll-formed steel and are a great option for both light-duty and heavy-duty applications. They have boltless arm attachments that enable speedier installation.

Structural Cantilever Racking: Systems for structural cantilever racking is constructed using structural forms and beams. They can manage medium- to heavy-duty applications better than others. A sturdy 4-bolt connection connects the columns and the extended arms.

The Top 5 Benefits of Cantilever Racks - How they Can Improve Your Storage Efficiency

Cantilever racking systems could aid to address numerous issues if you're thinking about how to make your warehouse storage operate a little bit more effectively daily. From promoting everyday productivity and making better use of space to protecting stock and workers, cantilever racks are becoming increasingly popular.

1. You Can Take the Stock Off the Ground: Floor space is essential for any industry and any warehousing operation. With the aid of cantilever storage racks, you may store your things safely and conveniently at a height while eliminating all stock and inventory from your warehouse floor.

2. Operations in warehouses can be accelerated: Your warehouse operations should run more smoothly with better organization and more space. Picking and storage proceed more quickly, there is more space to manage, and you can successfully meet increased demand from an expanding customer base.

3. You'll raise safety objectives: Cantilever storage racks are significantly safer than normal or antiquated practices of the past. Zyco, the best racking and shelving provider in UAE, methodically creates, fabricates, and installs custom racking to guarantee that bulky, heavy objects and stock are housed carefully and safely away from danger.

4. They are durable and heavy-duty: Cantilever racks can handle enormous pressure, huge loads, and general weather conditions in addition to years of use and ordinary wear and tear. Because of a cantilever rack's heavy-duty design, you may expect to store enormous things and bulky goods for the foreseeable future without worrying about damage.

5. They'll work both outside and inside: The versatility of cantilever rack systems extends to both indoor and outdoor settings. Inside your warehouse, you can set up specialized racking to scale up or you can construct a weatherproof outdoor storage solution under a canopy. Cantilever racking can assist you to expand your inventory and customer base when you just don't have enough room inside and require an outdoor storage bay.

How to Safely Install a Cantilevered Rack System?

Due to the lack of external vertical supports, cantilever racking differs from other storage solutions. Uprights, arms, and brace sets are the three primary parts of a cantilever rack. If any of the components seem to be damaged, or if any components are missing, do not continue with the installation. Refer to the packing list for the materials inventory. Let’s look into the steps of installing cantilever racks;

1. Set the rack footprint in place: Spread out the rack's footprint on the ground. Draw a chalk line marking the main aisle down the aisle, then draw a line defining the border of each cantilever baseline across the aisle.

2. Organize the starter bay on the ground: Set out the starter bay, which consists of two columns, the necessary bases, and the necessary arms, on the floor.

3. Connect the column with the base of the cantilever rack: Using the hardware included with your cantilever rack system, attach the cantilever rack base to the column.

4. Secure the floor with your cantilever rack: With the hardware, install the wedge anchors into the cement floor. As specified by the manufacturer of your cantilever rack, use shims.

5. Join the arms: Per arm, 4 bolts are needed. Connect the arms to your upright using the provided hardware, as specified by the calculations and specifications in the preceding section of this article.

6. Connect the arm's accessories: Use the hardware supplied by the manufacturer to fasten pipe stops or arm lips to the front of the arm if you're using them.

7. Build the second column: By attaching the base to the column, mounting the arms, and adding any additional arm accessories, erect the second column of your cantilever rack system by following steps 3 through 6.

8. Install the support: Once the arms and columns have been constructed, use the fasteners the manufacturer supplied to secure the bracing to the system's back. A few blows from an impact wrench or a worker using a standard spud wrench vigorously enough to bring the joined plies into firm contact can put structural connectors into the snug-tight condition.

9. Construct more adder bays as necessary: Continue to erect and construct adder bays to augment your starting bays while following the directions in stages 1 through 8 until the ideal rack system and footprint are reached.

If you are looking for a racking supplier, Zyco is the best and most trustful shelving and racking supplier in UAE, which provides high-quality cantilever racks.